General

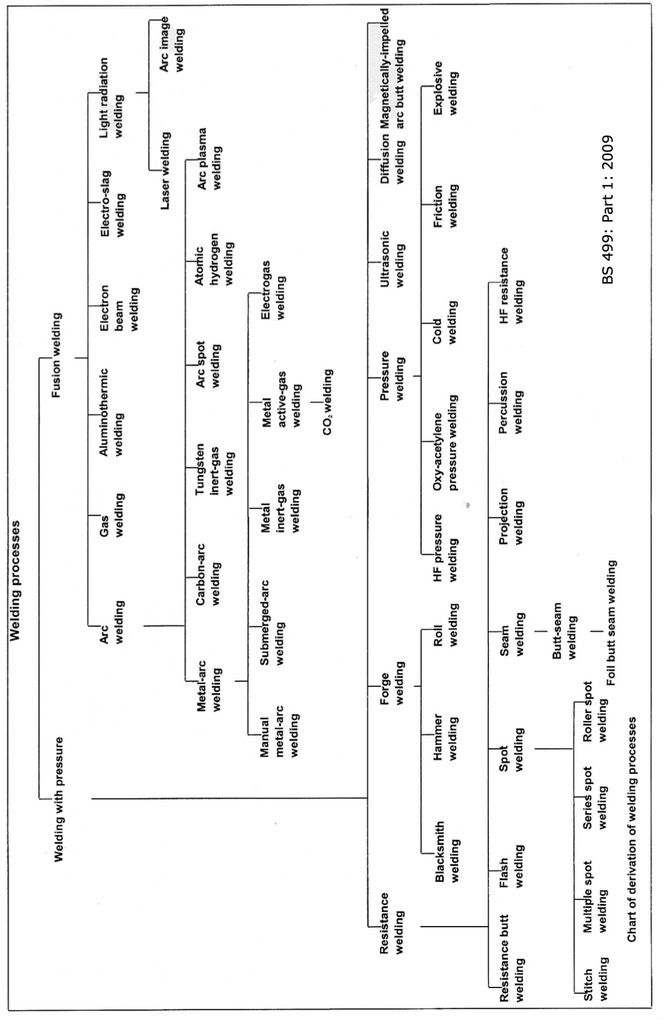

Welding is the process of joining two or more pieces of material together by bringing the atoms of each piece into such close contact that an atomic bond takes place, i.e. the separate pieces fuse together to form one.

This process is not restricted to metals, many materials such as plastic and glass can also be welded.

The first welding carried out was called forge welding. As the name implies, it was used in the forge or smithy by blacksmiths. The method involves heating the pieces of iron to be joined to red heat and hammering them together. Because no melting of the materials is involved, the process is termed hot solid phase welding or welding with pressure.

Welding with pressure is used to obtain a welded joint between two materials without melting them. The process involves the use of high pressures to bring the materials into close enough contact for an atomic bond to be obtained.

To achieve an atomic bond, the pressure applied must cause plastic deformation of the surfaces being welded in order to break up and remove the oxides on the surfaces. The weld is obtained by atomic diffusion followed by crystal growth across the surfaces being joined.

The application of heat, or the generation of heat due to frictional effects, has the effect of reducing the amount of plastic deformation required to produce a bond.

Welding with pressure has a low heat input when compared to fusion welding, this is advantageous for many welding applications. Welding with pressure can also join together dissimilar metals which are difficult to weld with any fusion welding process. However, fusion welding processes are more widely used than the welding processes involved with pressure.

Fusion welding is the alternative process to welding with pressure.

The fusion process relies on the properties of molten materials to easily form atomic bonds. When a material melts, the lattice structures which form the material are destroyed, allowing the atoms to easily mix together. Upon cooling and solidification, the atoms re-form into new lattice structures. These structures may well be different to the original lattice for various reasons, including the rate of heating, the temperatures reached, the rate of cooling, and any additions made to the molten material. Therefore the finished weld may have properties quite different from the parent materials.

Fusion welding processes require a local application of heat in order to bring the material to a temperature at which it will fuse, for steels this is approximately 1400°C to 1500°C. The temperature in the molten weld pool may be in the 2500°C to 3000°C range. The average temperature in the arc is 6000°C. This heat energy is dissipated into the surrounding atmosphere and parent material on either side of the weld.

Additions to the weld may be made unintentionally by exposing the molten material to the atmosphere. The gases which form the air (primarily nitrogen and oxygen) are readily combined with the molten metal and undesirable nitrides and oxides may be formed. It is therefore desirable to shield the molten weld metal from the air; most fusion welding processes incorporate a system to protect the weld pool from atmospheric contamination.

Weld Cladding Definition

Weld cladding is a recognised method of protecting against erosion and corrosion. Industry has developed, and is continuously improving, techniques for the application of cladding to a wide variety of components.

Weld cladding is a means of depositing a metallic layer onto a substrate to enhance the properties. The most common purpose is to enhance corrosion resistance and is commonly applied to boiler walls and roofs in utility boilers and energy-from-waste boilers. Cladding has been successfully deposited over large surface areas and in intricate, hard-to reach places in high value plant items. Additional applications include deposition of weld metal buttering to reinstate minimum design thickness requirements on vessels and tanks. The benefit of weld cladding is that it is a fused bond onto the substrate creating an integral layer with the component, eliminating the risk of the layer spalling or detaching during service and aiding volumetric inspection.

Buttering layer is often used between two different metals which are not directly compatible to weld together